Go to these pages for the theory of trackability and how to test for it. On this page we look at the tracking performance of the PHLUX-II active phono cartridge - a design specified for vinylistas, archivists and record-collectors alike.

Given the above, our advice is only to buy cartridges which have been properly specified for wideband tracking.

Remember that cartridge choice should not be on the basis of tracking ability alone; although it is precondition number one. A cartridge suitable for archival work or collecting must have a suitable vertical tracking angle, good frequency-response, low distortion and so on.

The PHLUX-II was tested using test records CBS STR-112, CBS STR-120, , Stereo Test Record HFS81, and Shure TTR-103. For all these tests, the PHLUX-II was mounted in our standard Technics SL-1200 Mk.II turntable. Downforce was set to 20mN (tracking weight 2g).

Using Shure's TTR-103 test record, the PHLUX-II cleared the 400Hz + 4kHz test to a level of 24cm/s, equivalent to 95µm. Even the last low-frequency track (at a real torture level of 30cm/s or 120µm) was negotiated with only marginal mistracking as the waveform and spectrogram (left) reveal. The compliance of the armature bearing in the PHLUX-II is adequate for all modern and historical records.

At middle frequencies, where tracking performance depends on the damping of the elastomer bearing, the PHLUX-II passed all except the last test. The penultimate test at 31.5cm/s was passed comfortably as the Lissajous display (left) indicates. This is a good result as maximum of 30cm/s on real records are occasionally reached, but never exceeded. The PHLUX-II will not mistrack on mid-frequency signals.

Here, the PHLUX-II passed all tests, right up to the 30 cm/s level as the spectrogram and waveform of the 30cm/s track indicate. The 270Hz component in the distortion signal is -46dB relative to the 10.8kHz level. According to Shure's calculation formula this gives a figure for DHIGH as 0.5% which is a very good result. The high-frequency tracking of the PHLUX-II is excellent. It will not damage records at its recommended playing weight.

In order to get a full picture of the mechanical performance of the PHLUX-II, the last two tests are devoted to looking at the dynamic performance outside the audio band (20Hz to 20kHz). First, sub audio-frequency performance and afterwards, performance above the audio band.

Conventional wisdom is to use the Hi-Fi News Analogue Test LP for the arm resonant frequency tests, but we have not found this disc to give consistently clear results. Lateral resonance is much more clearly identified with an old LP, the Stereo Test Record from Hi-Fi Sound (HFS81).

The results from this test record are illustrated (left) and reveal that the lateral resonance is almost exactly 10Hz. This frequency ideal as it falls in the "dead zone" between record-warp excitation and audio modulation when used with this popular turntable; as explained on this page.

As the waveform for the lateral resonance test indicates, the effect is well damped, with a measured Q of 0.707. The vertical resonance is even better damped - whch may have been why the results from the HFN Analogue Test LP proved so difficult to interpret.

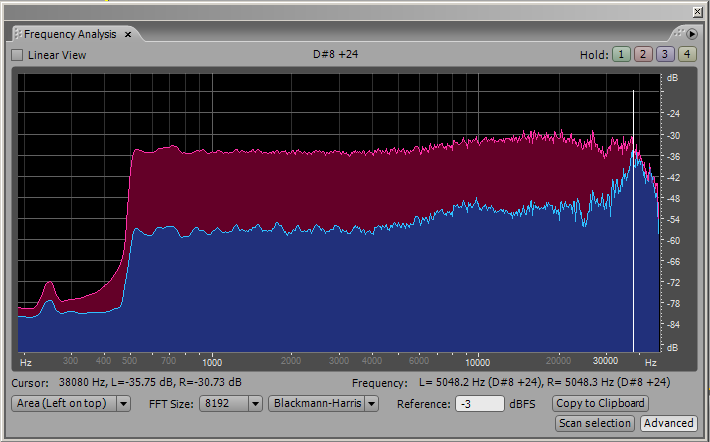

Not having an alternative test record to measure vertical resonance, we resorted to recording a section of silent groove which we matrixed for vertical movement in the DAW, and looked for the natural frequency of the tonearm bouncing on the compliance of the cartridge bearing. Sufficient signal level is usually provoked by the simple act of tracing the groove. (If not, a gentle tap near the tonearm pivot will provoke it.) The resulting trace and frequency analysis are illustrated (right).

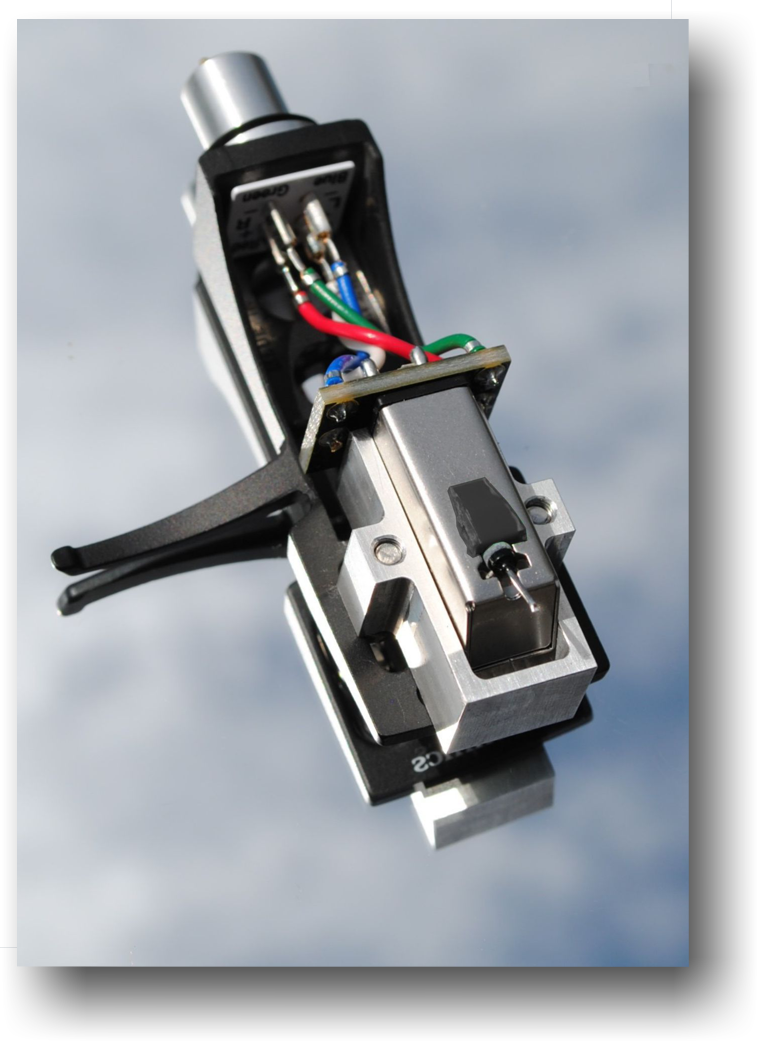

The effective mass of the Technics tonearm (with headshell but without cartridge) is 12g. The PHLUX-II weighs 8.5g, but most of this mass is behind the line of the stylus as illustrated in the photo at the top of the page. A few calculations show that the effect of this geometry reduces the effective mass of the cartridge at the stylus point to about 8g. This gives a nice, round figure of 20g effective mass for the arm and cartridge. The illustration reveals that the resonance is. once again, around 10Hz.

Using the formula, F = [2.Π.√(M.C)]-1, and knowing the values for frequency (F) and for mass (M), we can rearrange to solve for vertical compliance (C) to derive the value of 12.5µ(cm/dyne).

Measurements show that the PHLUX-II is almost perfectly matched to the Technics tonearm. This is good because the Technics tonearm is in the middle of the effective-mass range. So, the PHLUX-II is suitable in a wide range of tonearms.¹

One last piece of the puzzle is to look at the wideband response of the cartridge (to 50kHz), with CBS STR-120 test disc. The spectrogram of the result is given (left). Stylus resonance is betrayed by the almost complete crosstalk into the quiet-channel at the resonant frequency.

It's clear to see that the resonant frequency is almost exactly 38kHz in the spectrogram above; a high frequency given that the PHLUX-II employs an elliptical stylus (not a Shibata or other extended contact type). The trace also indicates that the resonance has almost no effect within the audio passband (≤20kHz) either upon frequency-response or crosstalk. The effective mass of the moving armature is low which accounts for the PHLUX-II's very good HF tracking. If we take the compliance of the record to be 0.05µ(cm/dyne) - a reasonable figure - the effective mass of the moving armature may be calculated to be 0.35mg which is at the lower end of the range of typical values.

In a normal moving-magnet cartridge, the result of this mechanical resonance is obscured by the resonant effects of pickup coil and cable capacitance. In this active cartridge, the mechanical resonance is evident - as in a moving-coil device.

The static (or very low frequency) compliance of the elastomer bearing in the PHLUX-II is well chosen to put the tonearm resonance comfortably in the 10Hz dead-zone with a medium-mass arm. This gives a wide range of choices for suitable tonearms and the PHLUX-II should match most tonearms well. The bearing compliance is also adequately dimensioned for maximum displacement for recorded frequencies below 1kHz. The bearing is not over-damped and this accounts for the good mid-frequency tracking, but it is sufficiently tamed to ensure excellent high-frequency performance. Good HF tracking is also secured by the very light armature.

1. Judging by on-line forums, there seems to be great angst regarding the proper matching of tonearms and cartridges. A lot of this is superfluous. Remember that the equation F = [2.Π.√(M.C)] -1 reveals that resonant frequency only changes with the square-root of the mass (or the compliance). So, if we say that the resonant frequency should be 10Hz ± 30% (a reasonable range of 7Hz to 13Hz), then we can say the product of tonearm effective-mass and cartridge compliance may vary by over 50% each way before exceeding our acceptable frequency range.

Address all mail to sales@phaedrus-audio.com